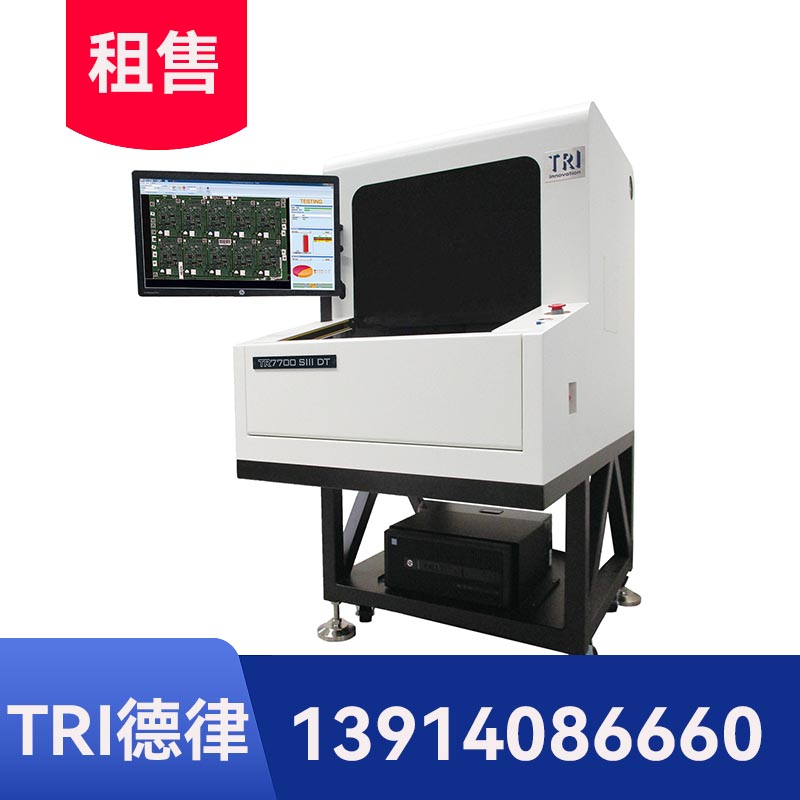

德律TR7700SIII3D介紹:

TRI開(kāi)創(chuàng)性的3D AOI解決方案,采用超高速混合式PCB檢測(cè)法,結(jié)合光學(xué)與藍(lán)光雷射3D真實(shí)輪廓測(cè)量,對(duì)于自動(dòng)化檢測(cè)不良現(xiàn)象可達(dá)到最大化覆蓋率。結(jié)合最先進(jìn)的軟體解決方案以及第三代智能化硬體平臺(tái),可提供穩(wěn)定且強(qiáng)大的3D 焊點(diǎn)與元件缺陷檢測(cè),具備高檢測(cè)覆蓋率與簡(jiǎn)易編程優(yōu)點(diǎn)。

德律TR7700SIII3D特性:

1.高速2D+3D檢測(cè),可檢測(cè)至01005元件

2.高缺陷覆蓋率,采用混合式2D+3D檢測(cè)技術(shù)

3.真實(shí)3D輪廓量測(cè)技術(shù),采用雙雷射單位

4.具備自動(dòng)化資料庫(kù)與離線編程功能的智能化快速編程介面

德律TR7700SIII3D規(guī)格:

Optical System

| Imaging Method | Dynamic Imaging with true 3D profile measurement |

| Top Camera | 4 Mpix |

| Angle Camera | N/A |

| Imaging Resolution | 10 μm, 15 μm (factory setting) |

| Lighting | Multi-phase RGB+W LED |

| 3D Technology | Single/Dual 3D laser sensors |

| Max. 3D Range | 20 mm |

Inspection Performance

| Imaging Speed | 4 Mpix@ 10 μm 2D: 60 cm2/sec 4 Mpix@ 15 μm 2D: 120 cm2/sec 4 Mpix@ 10 μm 2D+3D: 27-39 cm2/sec* 4 Mpix@ 15 μm 2D+3D: 40-60 cm2/sec* * Depending on board size and laser resolution |

Motion Table & Control

| X-Axis Control | Ballscrew + AC-servo controller |

| Y-Axis Control | Ballscrew + AC-servo controller |

| Z-Axis Control | N/A |

| X-Y Axis Resolution | 1 μm |

Board Handling

| Max PCB Size | TR7700 SIII 3D: 510 x 460 mm TR7700L SIII 3D: 660 x 460 mm TR7700 SIII 3D DL: 510 x 250 mm x 2 lanes, 510 x 550 mm x 1 lane |

| PCB Thickness | 0.6-5 mm |

| Max PCB Weight | 3 kg |

| Top Clearance | 25 mm |

| Bottom Clearance | 40 mm |

| Edge Clearance | 3 mm [5 mm optional] |

| Conveyor | Inline Height: 880 – 920 mm * SMEMA Compatible |

Inspection Functions

| Component | Missing Tombstoning Billboarding Polarity Rotation Shift Wrong Marking (OCV) Defective Upside Down Extra Component Foreign Material Lifted Component |

| Solder | Excess Solder Insufficient Solder Bridging Through-hole Pins Lifted Lead Golden Finger Scratch/Contamination |

Dimensions

| WxDxH | TR7700 SIII 3D: 1100 x 1670 x 1550 mm TR7700L SIII 3D: 1300 x 1650 x 1650 mm TR7700 SIII 3D DL: 1100 x 1770 x 1550 mm Note: not including signal tower, signal tower height 520 mm |

| Weight | TR7700 SIII 3D: 1030 kg TR7700L SIII 3D: 1250 kg TR7700 SIII 3D DL: 1150 kg |