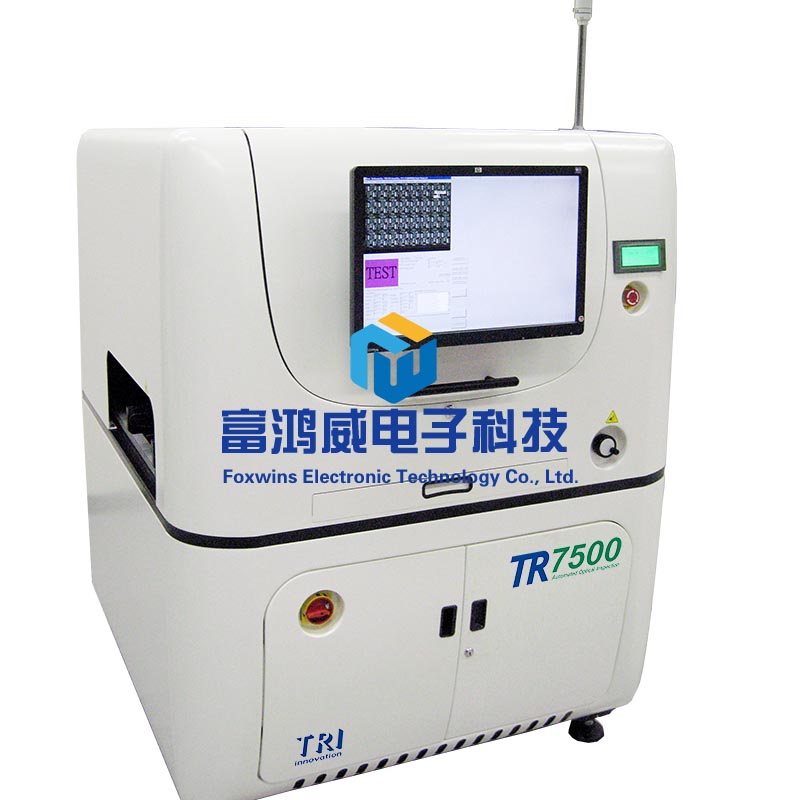

德律TR7500QE介紹:

TR7500QE AOI 藉由結合以四向可調變數位條紋光投影及四個低視角相機為基礎的新世代多角度2D和3D技術,提供了優越的3D錫點和元件組裝檢測功能。最新的檢測軟體采用快速CAD資料的編程及高度可客制化模板。

德律TR7500QE特性:

1. 多角度2D+3D覆蓋率

2. 四向數位條紋光投影

3. 四個低角度相機

4.3D高度檢測范圍可高達40 mm

5. 高速CoaXPress取像

6.可選配3D雷射模組

德律TR7500QE規格:

Optical System

| Imaging Method | Stop-and-Go Imaging |

| Top Camera | 12 Mpix |

| Angle Camera | 6.5 Mpix |

| Imaging Resolution | 10 μm, 15 μm (factory setting) |

| Lighting | Multi-phase true color LED, Coaxial lighting |

| 3D Technology | Quad Digital Fringe Projectors |

| Max. 3D Range | 12 Mpix@ 10 μm: 0-10 mm 12 Mpix@ 15 μm: 0-40 mm* * Need GPU card upgrade |

Inspection Performance

| Imaging Speed | 12 Mpix@ 10 μm: 13.5 cm2/sec 12 Mpix@ 10 μm: 23 cm2/sec with optional CoaXPress 12 Mpix@ 15 μm: 30 cm2/sec 12 Mpix@ 15 μm: 50 cm2/sec with optional CoaXPress Note: The inspection time will vary depending on the configuration |

Motion Table & Control

| X-Axis Control | Ballscrew + AC-servo controller (Linear motor optional) |

| Y-Axis Control | Dual driven ballscrew + AC-servo controller |

| Z-Axis Control | Ballscrew + AC-servo controller |

| X-Y Axis Resolution | 1 μm |

Board Handling

Inspection Functions

| Component | Missing Tombstoning Billboarding Polarity Rotation Shift Wrong Marking (OCV) Defective Upside Down Extra Component Foreign Material Lifted Component |

| Solder | Solder Fillet Height Solder Volume % Excess Solder Insufficient Solder Bridging Through-hole Pins Lifted Lead Golden Finger Scratch/Contamination |