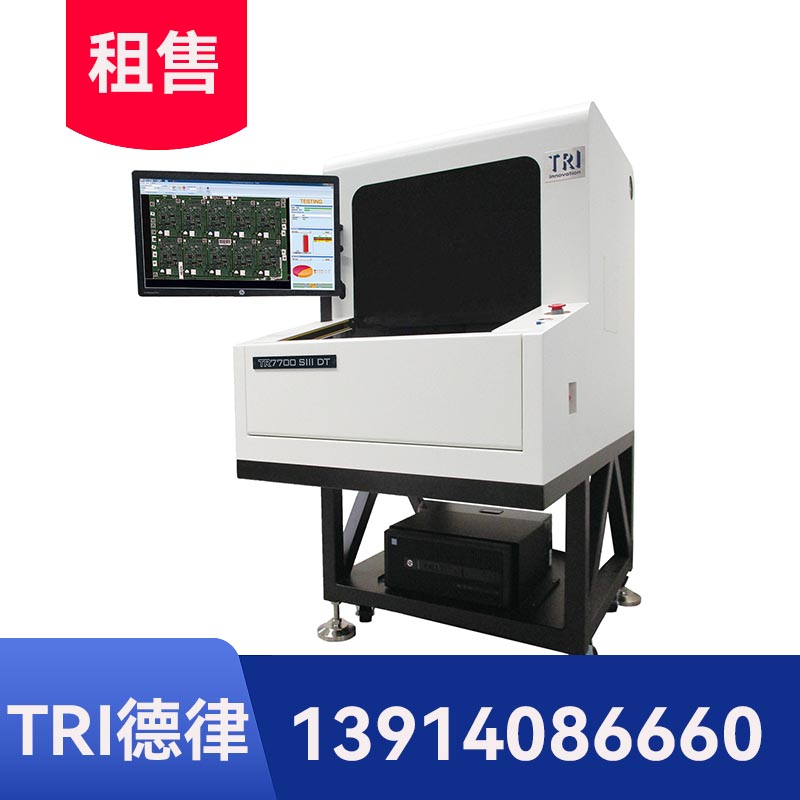

德律TR7700Q介紹:

TR7700Q 3D AOI 擁有數位四向條紋光投影技術,結合最新穎的2D+3D 檢測技術,為組裝電路板檢測領域掀起全新革命。全方位3D數位條紋光技術涵蓋檢測范圍廣闊,擁有極佳的精準性呈現極小共面缺陷及焊點問題。 TRI的3D錫點及爬錫檢測符合IPC標準,確保爬錫的品質。藉由檢查爬錫高度及體積,TR7700Q 3D AOI可檢測出少錫、缺錫、空焊等不良現象。

德律TR7700Q特性:

1.超高精準度 2D+3D AOI 走停式取像

2. 爬錫高度及體積檢測功能

3. 清晰且可靠的3D四光源數位條紋光

4. 可變頻3D檢測范圍高度高達 30 mm

5. 免空壓智能化自動運輸送帶系統(IACS)

德律TR7700Q規格:

Optical System

| Imaging Method | Stop-and-Go Imaging |

| Top Camera | 4 Mpix or 12 Mpix (factory setting) |

| Angle Camera | N/A |

| Imaging Resolution | 5.5 μm, 10 μm, 15 μm (factory setting) |

| Lighting | Multi-phase True Color LED |

| 3D Technology | Quad Digital Fringe Projectors |

| Max. 3D Range | 4 Mpix@ 15 μm: 0-30 mm* 12 Mpix@ 5.5 μm: 0-4 mm 12 Mpix@ 10 μm: 0-30 mm* *Need GPU card upgrade |

Inspection Performance

| Imaging Speed | 4 Mpix@ 15 μm: 21 cm2/sec 12 Mpix@ 10 μm: 14.5 cm2/sec 12 Mpix@ 10 μm: 23 cm2/sec with optional CoaXPress Note: Depending on component distribution |

Motion Table & Control

| X-Axis Control | Ballscrew + AC-servo controller |

| Y-Axis Control | Ballscrew + AC-servo controller |

| Z-Axis Control | Ballscrew + AC-servo controller |

| X-Y Axis Resolution | 1 μm with linear encoder |

Board Handling

| Max PCB Size | TR7700QI @ 5.5 μm: 330 x 330 mm* TR7700QI @ 10 μm, 15 μm: 510 x 460 mm TR7700QI DL @ 10 μm, 15 μm: 510 x 310 mm x 2 lanes, 510 x 590 mm x 1 lane *Depending on component distribution, the vailable PCB size could be different |

| PCB Thickness | 0.6-5 mm |

| Max PCB Weight | 3 kg |

| Top Clearance | 5.5 μm: 25 mm 10 μm: 50 mm 15 μm: 40 mm |

| Bottom Clearance | 40 mm [100 mm optional] |

| Edge Clearance | 3 mm [5 mm optional] |

| Conveyor | Inline Height: 880 – 920 mm * SMEMA Compatible |

Inspection Functions

| Component | Missing Tombstoning Billboarding Polarity Rotation Shift Wrong Marking (OCV) Defective Upside Down Extra Component Foreign Material Lifted Component |

| Solder | Solder Fillet Height Solder Volume % Excess Solder Insufficient Solder Bridging Through-hole Pins Lifted Lead Golden Finger Scratch/Contamination |